The Minimum Energy option of MIMO Random is implemented to handle the nonlinearity of a multi-shaker table and provide fast convergent control.

Read MoreExtracting the natural frequencies, damping shapes, and mode shapes of a structure aids in improving the design of the unit under test. In this case, the modal characteristics of a license plate is acquired by performing a modal analysis.

A MIMO FRF test is carried out using a pair of modal shakers and 14 accelerometers to obtain the vibration characteristics. The shakers impart energy to the structure for a longer period, which ensures an increased data set. The higher quality of the measurements also aids in the better estimation of the modal parameters.

Read MoreExperimental modal analysis (EMA) is based on forced excitation tests during which Frequency Response Functions (FRFs) are measured. However, real world loading conditions often differ considerably from those used in lab testing. Since all real-world systems are to a certain extent non-linear, the models obtained under real loading will be linearized for much more representative working points. Additionally, environmental influences on system behavior, such as pre-stress of suspensions, load-induced stiffening or aero-elastic interaction, will be taken into account.

Read MoreManufacturing plants often require controlled vibrations on various parts of the plant to run for several hours, days, or even weeks at a time. In some cases, continuous operation is required.

At these facilities, the affordable down time is limited to a few hours in a week. The continuous controlling and monitoring of independently running systems is another significant challenge. Monitoring each controller on a separate PC would require an unreasonable number of PCs to monitor. The necessity to run different types of controlled vibrations on these machines makes it impossible to use MIMO (Multi-Input Multi-Output) control. Also, when used with a single PC with MIMO control, memory and computational resources of the PC would become unreasonably high when the number of shakers needed to be controlled grows larger than 10.

Read MoreWatch Darren Fraser’s Multi-Resolution Overview presentation from this year’s ESTECH 2021 conference. Viewers will receive a brief review followed by several practical application examples. The Multi-Resolution function is patented by Crystal Instruments.

Read MoreWith the development of multiple shaker table systems, the availability of Multiple Input Multiple Output (MIMO) controllers and Multiple Input Multiple Output (MIMO) vibration control started emerging a couple of decades ago. Due to the readiness of standards, (e.g., Mil STD 810G, Method 527 and IEST DTE 022 working group recommendation) MIMO Testing has gained a huge momentum in the past decade. The increased usage of multiple shaker testing systems has been adopted by not only our military and defense industries, but also NASA, automotive, and many other commercial industries as well.

Read MoreModal testing and analysis are crucial processes in the product development cycle. Sometimes the testing results are wrong by several magnitudes, especially in the low frequency bands where the frequency resolution is not sufficient. Crystal Instruments’ patented Multi-Resolution (MR) Spectrum technology helps overcome this issue with a unique solution. A modal test is carried out to examine data obtained through regular FFT technology and MR technology to quantify the modal results, such as damping, FRF amplitude, Auto-MAC chart, and mode shapes.

Read MoreThere are many different shaker table arrangements based on various types of MIMO testing applications. The Multiple Shaker Table System ranges from Multiple Exciter Single Axis (MESA) to Multiple Exciter Multiple Axis (MEMA) with 2 to 6 shakers involved (e.g., three axis translational shaker table, four-poster, 6 DOF Multi Axis Shaker Table (MAST), etc.)

Read MoreThe output ground isolator is the most user-friendly solution for controlling multiple shakers while simultaneously improving accuracy of control and ensuring safe operation.

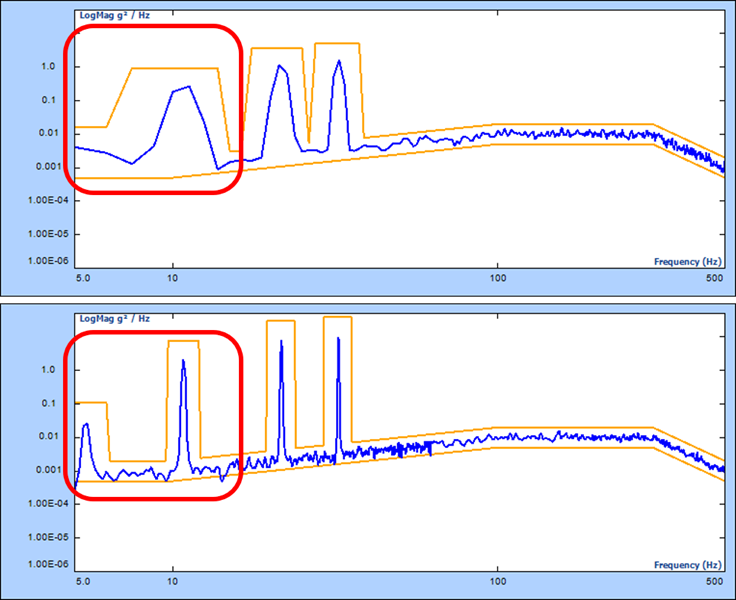

Read MoreIn this blog post, we will discuss the benefits of using Multi-Resolution, a feature available in Vibration Control Systems, to offer a better frequency resolution in the lower frequencies of the Sine-on-Random vibration spectrum. The same benefits are also applied to the general Random test, and Random-on-Random mixed mode test.

Read More