Product Testing & Evaluation Center

1548A Roger Dale Carter Drive, Kannapolis, NC 28081 | sales@sentekdynamics.com

Affordable vibration testing and combined environmental testing services from our Kannapolis, North Carolina testing lab, near the Charlotte metropolitan area.

Our in-house team provides expert assistance and service, contact us with your project details.

In-Flight Vibration Simulation

For aircraft, helicopter, spacecraft and turbine engine component and assembly qualification, product improvement and failure analysis.

Consumer Electronics and Appliances

Vibration and shock testing to ensure product safety and performance during use in their intended environment.Combined Temperature, Humidity & Vibration Testing

Department of Defense’s AGREE (Advisor Group on Reliability of Electronic Equipment) method of testing, combines three testing environments (temperature, humidity and vibration) in one chamber.Road / Off-Road Vehicles

Testing of automotive components and assemblies for durability, squeak and rattle and noise, vibration & harshness (NVH).Wave Slam Shock

Shock testing of shock mitigating seats for high-speed watercraft.Weapon Testing

Shock and vibration testing to ensure weapon safety, reliability and survivability during storage, transport and deployment.Missile Testing

Vibration testing to prove integrity of missile during storage, transport and firing.Spacecraft Engineering

Vibration and shock testing to verify structural integrity, performance and reliability of components and assemblies during all phases of flight.Wind Turbines

Component vibration and shock testing to determine design deficiencies and impact on performance, reliability and maintenance costs.

Down-hole Tools/Equipment

Vibration and shock testing to ensure tool and equipment performance and reliability beneath the earth's surface.

Real-World Testing

Simultaneous 3-axis testing for simulation of real-world environments and test time/cost savings.Production Testing

Vibration testing as part of acceptance testing to confirm performance of critical components and assemblies in the production process.Packaging and Transportation Testing

Vibration and shock testing to ensure package and product will survive hazards experienced in everyday shipping.Medical Devices

Vibration and shock testing to ensure reliability during use and conformance to physician and patient safety requirements.Marine

Vibration and shock testing of critical surface, sub-surface ship components and assemblies to ensure survival in adverse conditions.Military Standard Testing

MIL-STD-810, MIL-STD 167, MIL-STD-202,MIL-STD-750, NAVMAT P-9492 and more.Prototype Development

Vibration and shock testing to identify design flaws and reduce development time and cost.

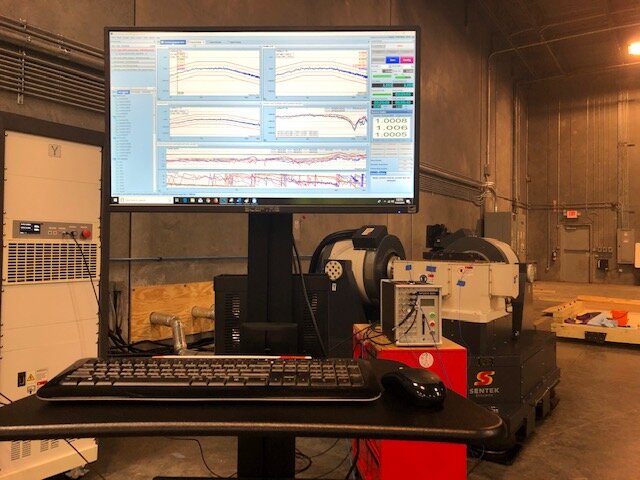

Simultaneous Three-axis Vibration Testing system

MA-1000-4H air-cooled simultaneous three-axis vibration testing system is designed to simulate real-world environments and satisfy MIL-STD-810G test requirements. It reduces test time by two-thirds for significant cost savings. Sentek Dynamics’ MA Series simultaneous 3-axis systems use Crystal Instruments’ Spider System vibration controller for advanced MIMO vibration control.

Max pk-pk displacement 51 mm (2 in)

Usable frequency range 5 - 2000 Hz

Max static payload 70 kg (154 lb)

Air-cooled amplifier efficiency > 90%

Air-isolation feet to eliminate need for seismic floor

Key Applications:

Testing in accordance with MIL-STD-810G Method 527 requirements

Testing in accordance with IEEE-344 multi-axis testing

Vibration qualification testing for aerospace/military components and systems

Automotive NVH/BSR and component testing

Features/Advantages

Simulates real-world vibration requirements

Reveals different possible DUT response dynamics under simultaneous multi-axis excitation in contrast to single-axis vibration testing

Identifies failures which could not happen with single-axis testing

Reduces testing time by two-thirds for significant cost savings over single-axis vibration testing in each axis

| SYSTEM PERFORMANCE | METRIC | IMPERIAL |

|---|---|---|

| Sine Force Peak per Axis kN (lbf) | 9.8 | 2,203 |

| Random Force rms per Axis kN (lbf) | 6.86 | 1,540 |

| Shock Force Peak per Axis kN (lbf) | 14.7 | 3,305 |

| Max Useful Frequency Range Hz | 5-2000 | 5-2000 |

| Max Displacement (pk - pk) mm (in) | 51 | 2 |

| Max Velocity m/s (in/s) | 1 | 4 |

| Max Static Payload kg (lb) | 70 | 154 |

Temperature, Humidity, & Vibration Testing System

THV-1200-5 AGREE Chamber (5° C/min) with 32 kN shaker with 800 x 800 mm low-pressure slip table

Key Applications:

Combined testing method also known as The Department of Defense’s AGREE (Advisor Group on Reliability of Electronic Equipment) method of testing, combines three testing environments (temperature, humidity and vibration testing) in one chamber.

Provides a quality, complete and integrated environmental test system to meet ever-changing reliability, qualification and ESS (Environmental Stress Screening) test requirements

Features/Advantages

Provides one comprehensive testing report

| THV-1200-5 Specifications | |

|---|---|

| Internal Volume (L) | 1200 |

| Interior Dimensions WxDxH (mm) | 1100x1100x1000 |

| Temperature Range (ᴼC) | -70 to 150 |

| Temperature Fluctuation (ᴼC) | ± 0.5 |

| Temperature Uniformity (ᴼC) | ≤2 |

| Temperature Deviation (ᴼC) | ± 2 |

| Temperature Ramp Rate (ᴼC)/min) from -45ᴼC to 80ᴼC) | 5 |

| Humidity Range (%RH) | 20 to 98 |

| Humidity Deviation (%RH) | ± 2 to 3 (> 75) |

| ± 5 (≤75) | |

| M3240A Specifications | ||

|---|---|---|

| SYSTEM PERFORMANCE | METRIC | IMPERIAL |

| Sine Force Peak kN (lbf) | 31.36 | 7050 |

| Random Force rms kN (lbf) | 31.36 | 7050 |

| Shock Force (6ms) kN (lbf) | 62.72 | 14100 |

| Useful Frequency Range Hz | 5-2500 | 5-2500 |

| Continuous Displacement mm (in) | 51 | 2 |

| Shock Displacement mm (in) | 51 | 2 |

| Max Velocity m/s (in/s) | 2 | 78.7 |

| Max Acceleration Sine Peak m/s² (g) | 980 | 100 |

Vibration Testing System with Head Expander

E20064A-PA3280-HST2500M water-cooled shaker, high-pressure 2500 x 2500 mm monobase slip table, w/optional automatic armature centering, motorized gearbox for shaker rotation, and foundation mounting or air-isolation mounts + 2500 mm square magnesium head expander.

Continuous displacement 51 mm (2.0 in)/76 mm (3.0 in)

Usable frequency range 5 - 2200 Hz

Max static payload 2000 kg (4409 lb)

Air-cooled amplifier efficiency > 90%

Rugged isolated trunnion

Key Applications:

The E-Series water-cooled electro-dynamic shakers are designed for the vibration testing of large-sized payloads up to 6000 kg (13,200 lb).

Ideally suited to test large-sized electronic parts, connectors, hand-held units and mechanical assemblies.

| SYSTEM PERFORMANCE | METRIC | IMPERIAL |

|---|---|---|

| Sine Force Peak kN (lbf) | 196 | 44,000 |

| Random Force rms kN (lbf) | 196 | 44,000 |

| Shock Force (6ms) kN (lbf) | 392 | 88,000 |

| Useful Frequency Range Hz | 5-2200 | 5-2200 |

| Continuous Displacement mm (in) | 51 | 2.0 |

| Shock Displacement mm (in) | 51 | 2.0 |

| Max Velocity m/s (in/s) | 2 | 78.7 |

| Max Acceleration Sine Peak m/s² (g) | 980 | 100 |

Vibration Testing System with Head Expander

L0620M-PAS106 air-cooled shaker system ideally suited to test small sized electronic parts, connectors, hand-held units and small mechanical assemblies. Featuring HES1200M-1000/560 Head Expander.

Continuous displacement 51 mm (2.0 in)

Useable frequency range 5 - 5000 Hz

Max static payload 200 kg (441 lb)

Air-cooled amplifier efficiency > 90%

Rugged isolated trunnion

Key Applications:

Electronic parts and systems - qualification testing

Computer equipment vibration testing

Automotive component vibration testing

Satellite component vibration testing

General stress screening

| SYSTEM PERFORMANCE | METRIC | IMPERIAL |

|---|---|---|

| Sine Force Peak kN (lbf) | 5.88 | 1,320 |

| Random Force rms kN (lbf) | 5.88 | 1,320 |

| Shock Force (6ms) kN (lbf) | 11.76 | 2,640 |

| Useful Frequency Range Hz | 5-5000 | 5-5000 |

| Continuous Displacement mm (in) | 51 | 2 |

| Shock Displacement mm (in) | 51 | 2 |

| Max Velocity m/s (in/s) | 2 | 78.7 |

| Max Acceleration Sine Peak m/s² (g) | 980 | 100 |

Dual Shaker Vibration Testing System

M5044A-PA155-LST900M air-cooled shaker system ideally suited to testing medium-sized electronic parts, flight and ground vehicle components and assemblies.

Continuous displacement 51 mm (2.0 in)

Useable frequency range 5 - 2500 Hz

Max static payload 1000 kg (2205 lb)

Air-cooled amplifier efficiency > 90%

Rugged isolated trunnion

Key Applications:

Automotive parts and systems - qualification testing

Electronic assembly, computer equipment testing

Avionics and military hardware vibration testing

Satellite component vibration testing

Product and package vibration testing

General stress screening

| SYSTEM PERFORMANCE | METRIC | IMPERIAL |

|---|---|---|

| Sine Force Peak kN (lbf) | 49 | 11,010 |

| Random Force rms kN (lbf) | 49 | 11,010 |

| Shock Force (6ms) kN (lbf) | 98 | 22,000 |

| Useful Frequency Range Hz | 5 - 2500 | 5 - 2500 |

| Continuous Displacement mm (in) | 51 | 2 |

| Shock Displacement mm (in) | 51 | 2 |

| Max Velocity m/s (in/s) | 2 | 78.7 |

| Max Acceleration Sine Peak m/s² (g) | 980 | 100 |