What’s Required to Bring Vibration Testing In-House?

So the question is on the table. Should we use an external laboratory to do our vibration tests, or purchase equipment and do the work in-house? Clearly, using an outside facility avoids the capital costs to build and equip our own testing laboratory. We avoid all of the facility running costs and testing equipment maintenance and we don’t need to cultivate our own vibration testing expertise. But, having our own equipment would give us far better control of scheduling, avoid repetitive packing and transport issues and provide us with better security. Further, having such equipment at hand and people who know how to work with it will likely be a huge aide if a new (or revised) product exhibits quality problems detected by vibration testing.

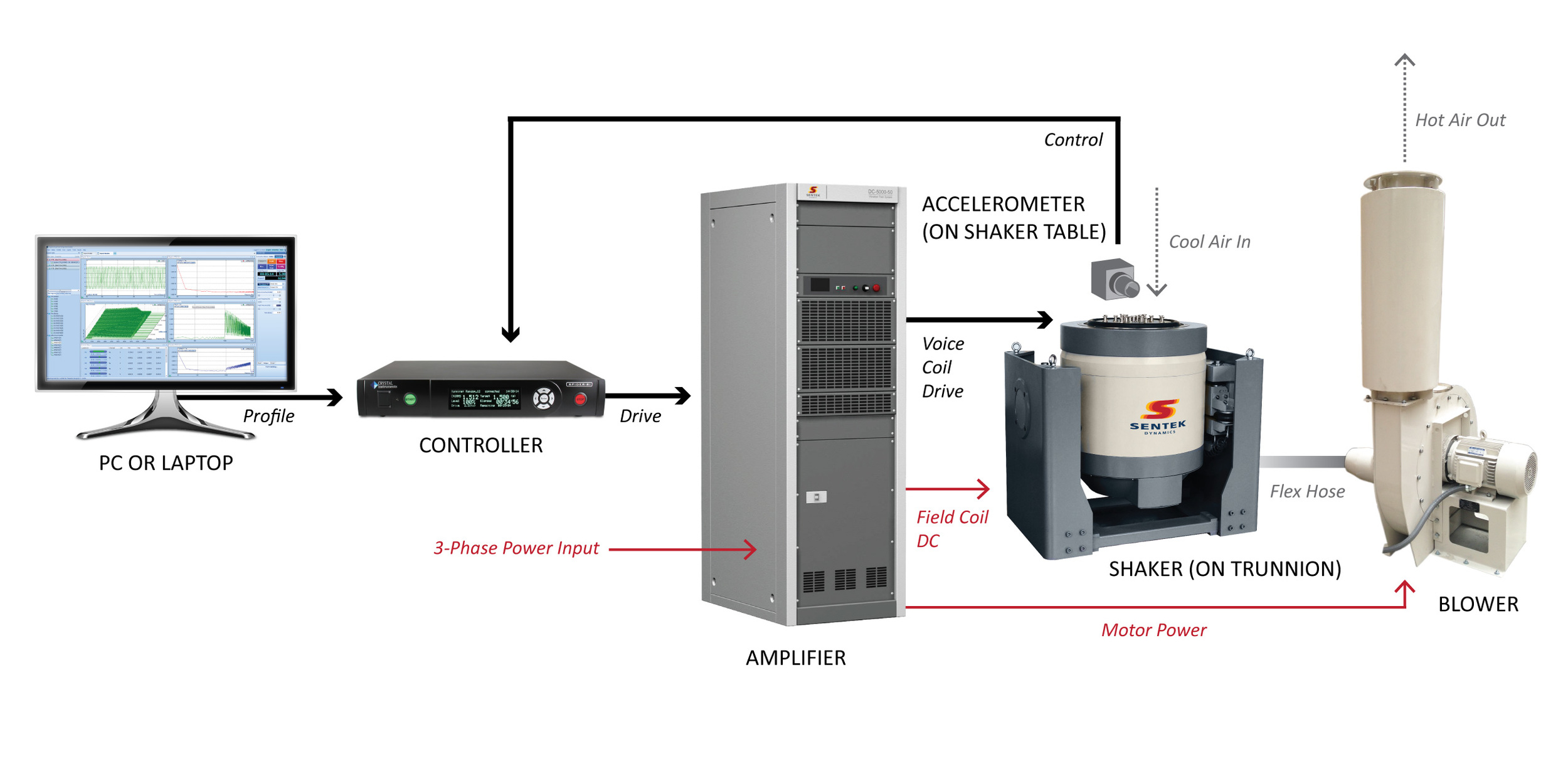

The Elements of a Vibration Testing System

What’s involved in setting up a new vibration testing laboratory? First off, you will need to select the right equipment to run the test or tests you are planning to execute. Most people start with a “vertical only” shake capability and select an air-cooled shaker in the low to medium force range. At minimum, your new system will include a vibration controller, a shaker, an amplifier and a blower. The Controller is the “brain” of the system. It uses an accelerometer on the shaker table (occasionally on the tested specimen) to measure the vibratory motion during a random, swept sine or shock test. The required details of the test are loaded into the controller from a personal computer (PC). The controller continuously compares the measured Control signal to the desired reference Profile specified for the test and computes the necessary Drive signal for the shaker to force the Control to match the Profile. The controller also can perform a myriad of analytical support functions including pre-test feasibility analysis and protective limit measurements during the test.

The amplifier is the closed-loop’s “power broker and operational cop”. Its fundamental mission is to power amplify the low voltage Drive signal from the controller and apply a high-current version of it to the shaker’s voice coil. But, it also provides a strong constant DC current to the shaker’s field coils and 3-phase electrical power to the cooling blower. The amplifier’s control module constantly monitors that all high-power system components are operating safely with all voltages, currents, temperatures, air flow and vibratory stroke within specified allowable values.

The shaker provides the system’s “brawn”, the electromechanical muscle needed to provide sufficient force to move the device under test (DUT) at the vertical acceleration level required. In order to do this, it must have sufficient force, stroke and acceleration capacity. It must also have a frequency bandwidth that meets or exceeds the test’s specification. Further, it needs the capacity to statically support the device under test and must have a sufficiently large load table to properly attach and support the DUT. In some instances, shaking the DUT horizontally is essential. In this case, the shaker is tipped to the horizontal and used to drive a slip table through a driver bar. The slip table and shaker may be purchased as separate free-standing components, or in a common mono-base for easier conversion from horizontal to vertical operation.

The blower cools the shaker. It draws cool laboratory air in through a filter surrounding the load table. The air flows down over the voice coil and the field coils, past the iron magnetic pole pieces and into an air chamber that is evacuated by a flexible hose leading to the blower. The heated air exits the blower through a silencer. For small systems, the blower may be located in the shaker space. To avoid recirculating the hot air, the blower’s outlet may be vented to the outdoors. For large systems, the blower itself is located outside reducing both noise and recirculated heat.