Introduction to Shock Testing in EDM-VCS (Vibration Control Software)

Developing a new product for commercial or defense application may require a wide range of tests to prove the strength and durability of a design. Shock testing is often required to ensure a product can endure the wear and tear it will experience when it is used in the real world. Finding the right equipment capable of performing these tests and conforming to industry standards is critical to delivering a successful product. Sentek Dynamics offers systems that conform to automotive, military, and commercial testing standards, including MIL-STD-810F, IEC68-2-27, UN38.3, and more.

Sentek Dynamics provides complete solutions for users to perform a variety of shock tests with adaptable systems capable of performing half-sine, post-peak sawtooth, and trapezoidal waveform shock tests.

Select the “Classical Shock” option (see figure 1.) at the start page of EDM Spider-VCS software to set up a classical shock test.

Figure 1. EDM Spider-VCS Start Page

Users can set the number of shock pulses and interval between pulses in “Test Configurations” (see figure 2). Setting a sufficient interval between pulses is critical to allow the energy from the shock to dissipate before continuing with the next pulse, ensuring clean shock pulses and good data.

Figure 2. Test Configurations – Test Parameters

In “Pre-test Parameters”, the pulse can be set as a positive or negative pulse (see figure 3).

Figure 3. Test Configurations – Pre-test Parameters

The “Test Profile” tab is where the actual shock waveform is defined (see figure 4). The user can set the pulse type, amplitude, and duration of the waveform. Users can select pulse tails for the required testing standard, adjust abort lines and edit shock waveform compensation parameters. The percentage of the system capability used by a specific waveform is displayed in the lower right corner of the window.

Figure 4. Test Configurations – Test Profile

The number of pulses performed in a test can be set in the “Run Schedule” tab (see figure 5). Low level pulses can be programmed at the beginning of a test to ensure the system is functioning optimally before full-level pulses begin. The shock profile has now been defined and the user can begin testing.

Figure 5. Test Configurations – Run Schedule

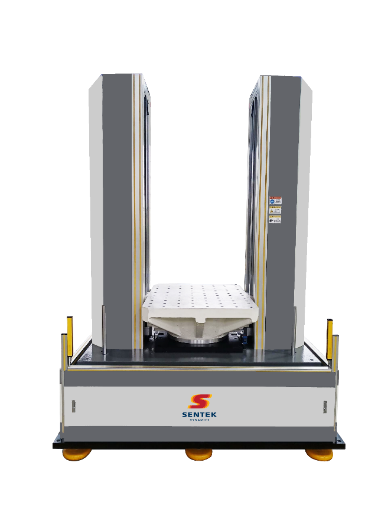

This summer Sentek Dynamics’ testing lab in Charlotte, North Carolina will be commissioning its first high-energy shock testing system, the SM-HE200. This system will be capable of testing payloads up to 200 kg, acceleration forces of 1000 g, and pulse durations ranging from 3 to 60 milliseconds. This is the first in Sentek Dynamics’ new Shock Testing line. Contact Sentek Dynamics to learn more about our upcoming pneumatically powered vertical and horizontal shock testing lines.