Two somewhat arbitrary types of excitation signals are Pseudo Random and Periodic Random. The characteristics of these two signal types will be discussed in detail here. The results of using these excitation types will be compared to the more popular Pure Random and Burst Random types. It will be shown that the cost of additional testing time is well worth the superior estimation of MIMO FRF signals.

Read MoreSentek Dynamics utilizes Crystal Instruments’ Random Vibration Testing System to address the 6-Amazon.com testing requirements. Contract environmental testing services are provided at our testing facility in Charlotte, North Carolina. The THV Environmental Testing system provides one comprehensive testing report for the user’s convenience. Consult with a Sentek Dynamics representative to discuss the right solution for your needs.

Read MoreLithium-ion batteries are gaining popularity as the most common battery type used for electric vehicles. During their lifespan, these batteries undergo a variety of vibrations and temperature changes. Several common test standards have developed to simulate the long-term environmental effects on these batteries across different size levels (e.g. cell, module, pack).

Of the many test standards for EV batteries, this post will specifically focus on the vibration and temperature aspects of four well-known standards: SAE J2380, SAE J2464, IEC 62660-2, and UN 38.3.

Crystal Instruments Spider systems can provide solutions for random, sine, and shock vibration test, as well as temperature control.

Read MoreIn this case, the modal characteristics of an airplane model is acquired by performing experimental modal analysis. A SIMO FRF test is carried out using a single modal shaker and multiple sensors to obtain the vibration characteristics. Shaker excitation provides better consistency and repeatability than a modal hammer. It also produces a cleaner data set because of a greater average. The higher quality measurements lead to a better estimation of the modal parameters.

Read MoreMulti-Sine is a new type of Sine test which facilitates multiple sine tones sweeping simultaneously at once. In automotive testing, engine mounted components such as fuel lines, turbos, headers, sensors, heatshield… are all subjected to high vibration levels during their operational life cycle. High cycle fatigue testing of engine mounted components is often done with a standard Swept Sine test. By performing a Swept Sine test, all resonances within the frequency ranges are excited and measured.

Read MoreEarthquake testing is a crucial process that is used to determine the seismic performance of a structure. The utilization of a physical testing method helps users better understand the complexity involved in earthquake forces. A shaker table is typically used to execute a physical method of testing. The results from earthquake testing are used to optimize the design and material properties of the unit under test.

Read MoreMultiple-Input Multiple-Output (MIMO) vibration testing has increased in popularity as a result of the development of multiple shaker table systems and the availability of MIMO vibration controllers. The readiness of standards such as Mil-STD 810G Method 527 and the IEST DTE 022 Working Group Recommendation have also contributed to the huge momentum MIMO testing has gained in the past decade. Military and defense manufacturers are not the only industries adopting multiple shaker testing. Manufacturers in aeronautic, space, automotive, and the commercial electronics industries are also benefiting from the advantages of multiple shaker testing systems.

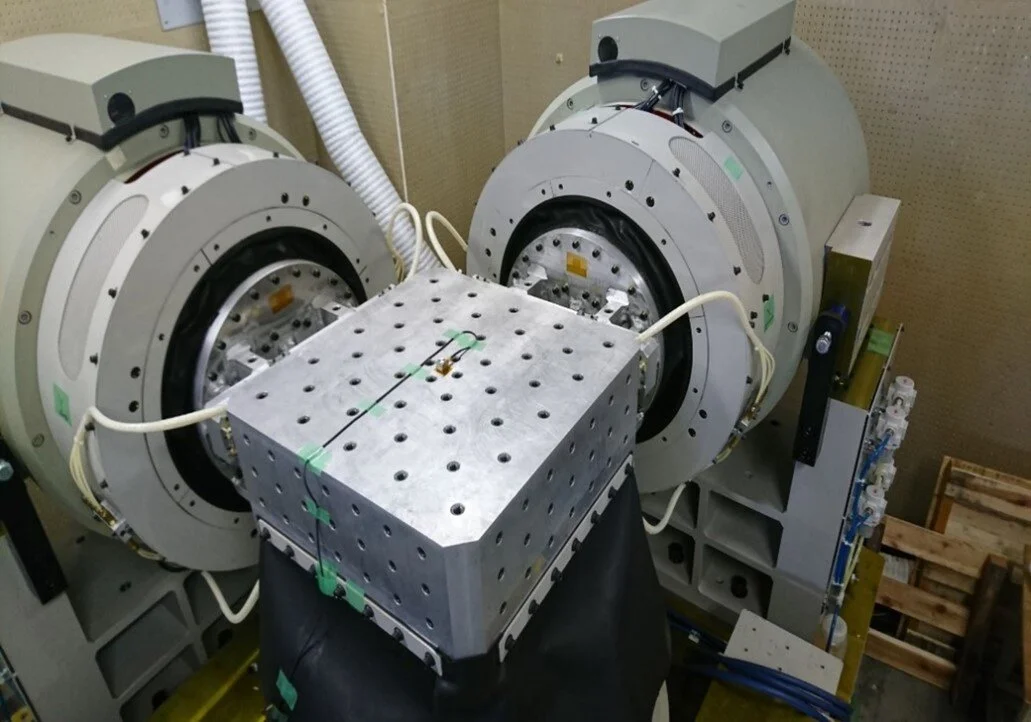

Read MoreSingle axis vibration control tests are widely used to qualify the behavior of the unit under test (UUT). If the UUT passes the test requirement then it provides confidence about the sustainability and durability of the test structure. However, sometimes excitation in multiple directions is required to test the robustness of the UUT which has led to the wide use of Multiple-Input Multiple-Output (MIMO) testing for the programmed test profiles. It is therefore important to make sure that the hardware setup allows for the unit to be tested in various configurations of single axis, dual axis, or three-axis. However, it takes long hours to manually change the setup because of the components (shaker setup, slip table, driving bar, fixture, etc.) involved.

Read MoreDual excitation shaker systems are commonly used to test long or heavy devices under test (DUT). When the device under test is very long or too heavy, a single shaker cannot perform the test because of oversized dimensions or a large driving force. Thus a dual excitation shaker system is arranged as the solution. Users can fix the longer sized or heavy DUT horizontally or vertically on top of a dual excitation shaker system. Common arrangements are horizontal push-push, push-pull, and vertical.

Read MorePreventive maintenance is maintenance that is performed on operating equipment to ensure optimum performance and reduce the likelihood of a failure at an inopportune time. Maintenance strategies for electro-dynamic vibration testing systems (shakers) range from reactive (run to failure) to predictive maintenance, where the aim is to predict failures before they occur. Regularly scheduled maintenance, a.k.a. preventive maintenance, lies between reactive maintenance and predictive maintenance and offers numerous benefits in cost, and system reliability and performance.

Read More