Smart Battery Pack Testing with EDM

Battery packs are one of the two main components relied on by Electric Vehicles (EV) for vital parameters such as speed, mileage, and torque. Hundreds or thousands of battery cells must be combined to provide the demanded voltage and current required to drive electric vehicles (EV). For example, the Tesla Model S 85 kWh contains around 7,000 battery cells. When considering factors such as cost, life span, safety, performance, and energy efficiency, most EV manufacturers choose lithium ion batteries. However, the large number of batteries required combined with the unstable nature of lithium cells poses significant challenges in designing a battery pack for an electric car.

A battery pack has an enclosure to protect battery cells from external hazards, such as external forces and moisture. An internal cooling system and Battery Management System (BMS) provides a protected environment for the cells to perform in.

While performing vibration or THV (temperature/humidity/vibration) tests on a battery pack, accelerometers, temperature, and humidity sensors can measure the external environment of the battery pack. The BMS monitors the status of internal battery pack and communicates with external components via CAN bus.

With the integrated CAN bus support in EDM, EDM can monitor the internal and external status of the battery pack and take actions according to pre-defined conditions.

The following is an illustration of the connections in the system, including a battery pack, CAN bus adapter, THV/VCS controller, sensors, and a computer.

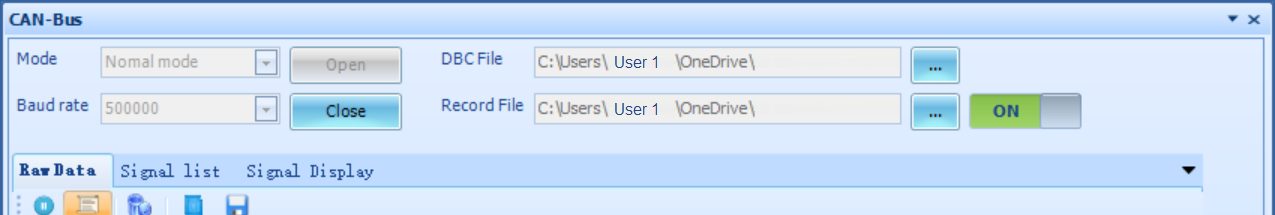

On EDM, the CAN bus feature is located under the Set-up menu.

The software may configure the CAN bus adapter to normal mode, listen only, or self-test to verify the connection and the adapter itself.

The main functions of the CAN bus feature are to view raw data, configure signal properties, configure alarm and abort limits of each signal, and view signals. Each signal from CAN bus may represent a status of a component in the battery pack, such as voltage, current, or temperature of cells.

CAN bus data displayed along with live signals presents the external and internal conditions of the battery pack in an overall and integrated view.

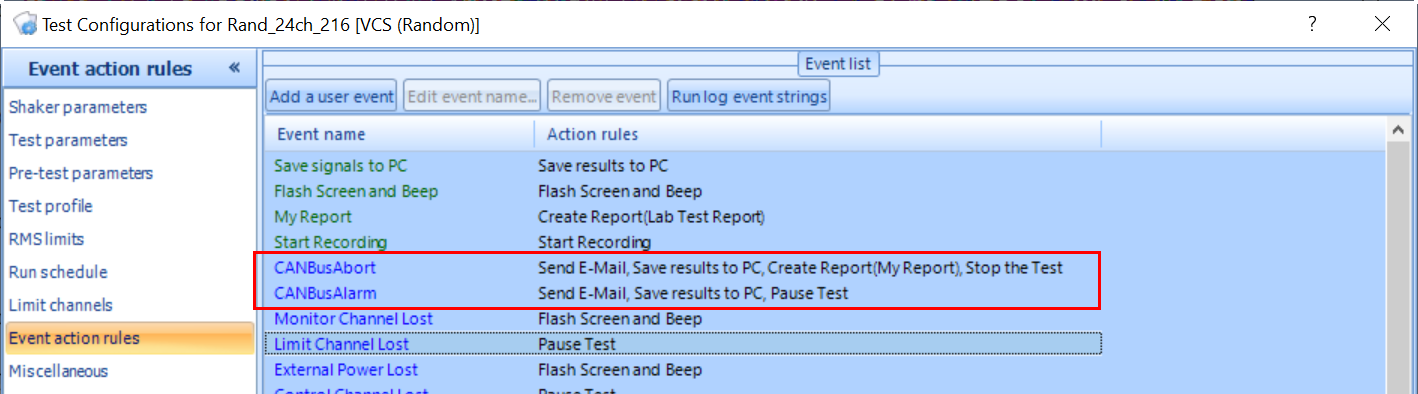

EDM features convenient event action rules such as signals highlighted in color codes when the alarm or abort limit is exceeded. The user may define the required actions to be taken when a signal received from CAN bus exceeds a limit.

Battery packs are volatile because of the hundreds or thousands of cells contained inside. To ensure safety, the combined vibration and THV testing must be stopped before the battery pack enters an unstable or limit condition. The operator is required to continuously monitor the test, which consists of two separate software programs running vibration and THV testing while reading the battery pack’s status from CAN bus. The built-in CAN bus feature in EDM allows the software to take over the tedious task of monitoring and reacts in time without error.