Vibration Testing Lab

Control Room

(Page 3)

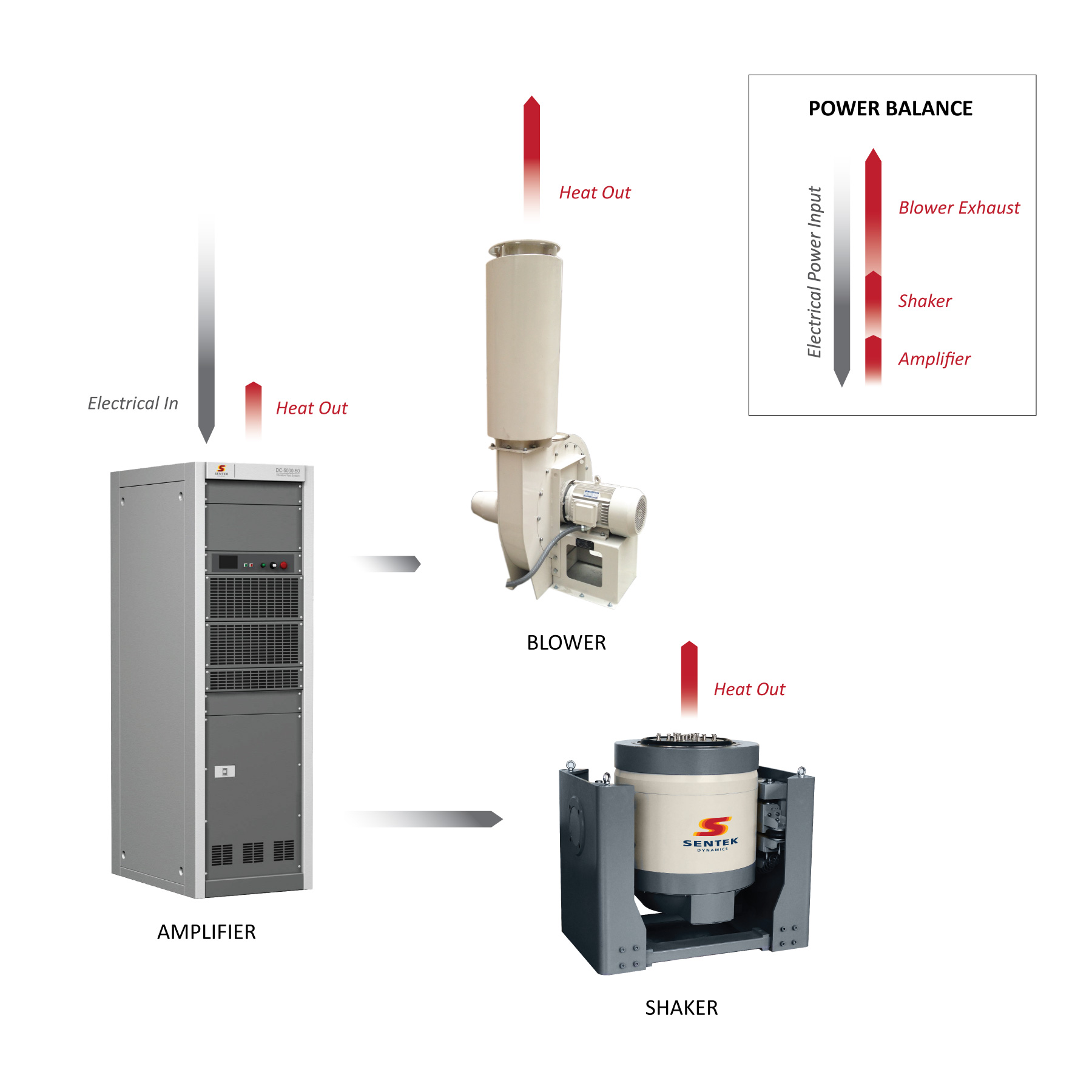

Dealing with Heat

Heat is always an issue with an electrodynamic shaker installation as a significant amount of electrical power is consumed in operation and converted to heat. It is essential to review the heat load survey for the proposed space; additional air-conditioning capacity is likely to be needed. This should be brought on-line before the laboratory is commissioned. All Sentek Dynamics PA series amplifiers are highly efficient class-D switching amplifiers. They have a thermal efficiency of 90%. Cooling efficiency is harder to characterize and varies significantly between systems. The “big picture” issues are that the total heat generated by the system (the system’s heat output) is equal to the electrical power input to the amplifier. For the shaker at “full song”, the worst case heat load (in BTU/hr) is equal to 3412 times the amplifier’s kVA rating. System heat is given off by the amplifier, the shaker and the blower as well as the blower exhaust. Venting the blower’s exhaust to the outside dispels better than 50% of this heat. Placing the blower outside further reduces the laboratory heat load and the noise level.

We’re Here to Help

Creating a vibration test laboratory is a big job. But, as with any engineering project, breaking it down into a series of tasks to be accomplished makes the effort manageable. The Application Engineering staff of Sentek Dynamics is experienced in creating and debugging new installations. They are available to help you during the planning, construction, commissioning and daily use of your new facility.