(Page 1)

Planning the Laboratory Space

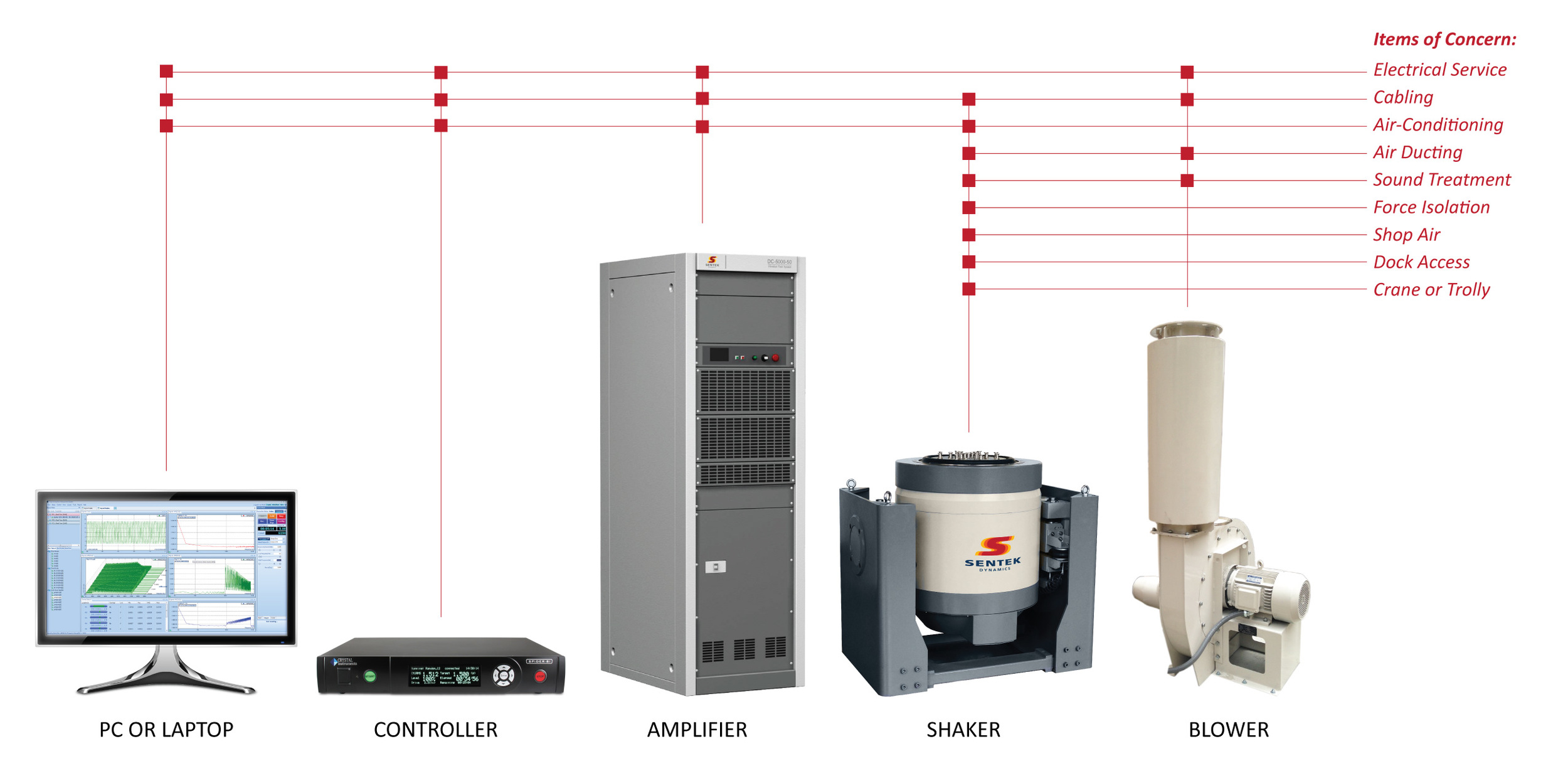

There are a lot of things to be considered in planning a new vibration laboratory beyond what equipment to buy. The dots in the figure below denote 21 “what and where” considerations that you don’t want to overlook. Clearly you need to know the size and weight of everything your lab will house as a start point. You need enough floor space to house everything comfortably, allowing equipment to be used and serviced efficiently. You should plan for at least one meter (3 feet) clearance between the shaker, amplifier, blower and walls, benches or other obstructions. The floor needs to be level and strong enough to tolerate any equipment you need to use to move the test equipment initially and test items thereafter. You’ll also need cabinet space to store fixtures and tools and supplies of all sorts.

You need enough ceiling height to get large items in and out. If you are going to test large items, you will need an overhead crane near the shaker and possibly trolley access. You’re going to need 3-phase electrical power for the amplifier rack and single phase outlets for work lights and power tools near all elements of the system. There will be a lot of wiring and you need to plan for its orderly arrangement in protective wiring troughs allowing maintenance access. You will need clean shop air (ISO 8573-1: class 1.7.1, 0.01 micron particle size, 0.01 ppm oil content) at the shaker. There will be a flexible duct between the shaker and blower. It needs to be safely routed and preferable sound insulated. The blower (or at least its discharge) should be outside of the work area. You will need air-conditioning – your shaker system will impose a significant added heat load on the workspace.

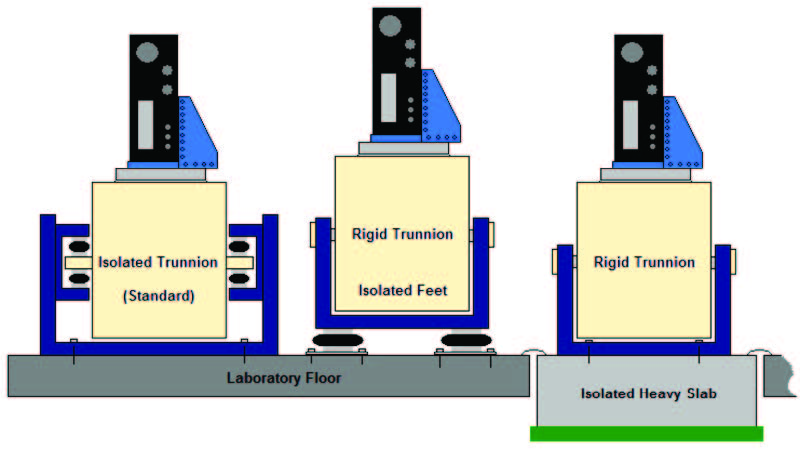

Your lab floor will need to be strong and level – it will be supporting a lot of heavy items. Unfortunately, that strong floor can make your activities very unpopular with other inhabitants of the building. It can transmit the reaction forces of the shaker throughout the building, causing noise and even resonant vibration. Unless properly dealt with, this can be a real source of annoyance. The ideal answer is to situate your shaker on a separate floor slab, isolated from the remainder of the building. When this is not possible, our standard isolated trunnion or air-spring isolators under the feet of your machine can help enormously.