(Page 3)

Control

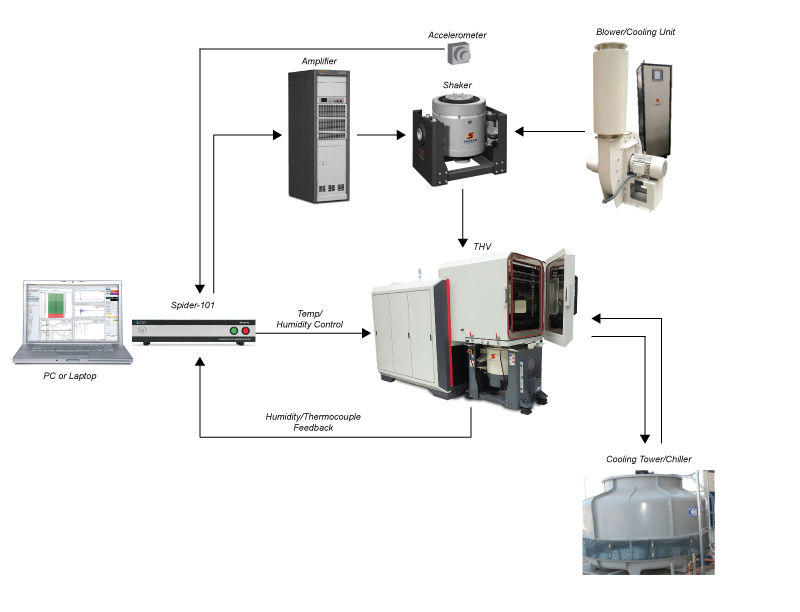

One of the many advantages of a Sentek Dynamics’ THV Series system is that it incorporates the Spider-101 controller which can control temperature, humidity and vibration control simultaneously. Using Multiple Input Multiple Output (MIMO) PID decoupled control, simultaneous control of individual environmental testing systems to high accuracy is accomplished. Due to enhanced control design, the DUT is able to experience prescribed vibratory motion of sinusoidal, random or transient form (or a combination of any of these) while being exposed to a specific user-defined temperature and humidity environment. The Spider-100 controller supports Crystal Instruments’ versatile Environment Data Management (EDM) vibration control software (VCS) and dynamic signal analyzer (DSA) software.

The Spider-101 is specially developed for combined temperature, humidity and vibration testing where the device under test (DUT) is subjected to simultaneous temperature cycling, variable humidity and vibration. The unique capability of simultaneous control for combined testing is made possible by excellent control design which allows for control of a shaker, refrigeration units, electric heating elements and humidification components.

General THV System Facility Installation Preparation Guidelines

Once you have identified the ideal THV system for your testing requirements, the next steps in the process will be to evaluate your facility for suitability, establish the optimum placement of your equipment, and verification of facility services.

Facility Sizing and Component Placement

One of the most crucial factors when determining the suitability of your potential test site will be ensuring the chosen location provides sufficient floor space for not only the THV system but also the human component of your laboratory.

When analyzing the size requirements for your lab some key points to consider will be:

Component placement – The main components of your THV system will be:

THV chamber

Shaker in either vertical only or mono-base vertical/horizontal configuration

Amplifier(s)

Cooling equipment – Blower for air cooled systems or cooling unit for water cooled systems

Hydraulic Power Supply (HPS) – For high-pressure slip-tables only

Operator’s control area or room

Required length of interconnections between each piece of equipment

Ability to maintain a minimum of 1m/3ft of clearance around all components when installed

Movement – The chamber will move in two axes.

- When moving vertically, consideration must be taken to ensure that there will be sufficient clearance between the chamber in the full vertical position and the laboratory ceiling.

- Depending on the model of shaker chosen for your THV system, the chamber will move horizontally to either two or three distinct positions. 1. Maintenance position – This will be the position used for chamber only or vibration only testing and performing any required maintenance to the THV system. 2. Vertical combined testing. 3. Horizontal combined testing if using a shaker with a mono-base slip-table.

- In any of these possible horizontal movement positions, sufficient room will be required for: movement of personnel, opening of chamber door, opening of THV access panels, and loading/unloading of any fixtures and/or DUTs including movement of any equipment required to do so.

Installation access – Your THV system will arrive at your facility with each individual component crated and fully assembled. The largest item will be the THV chamber itself. Entryway and path of travel large enough to accommodate the THV chamber and the equipment being used to facilitate its movement must be provided.

Facility Supply Requirements

Your facility must have certain features and services to properly install and operate your THV system.

- The floor will need to be level, capable of supporting the weight and operation of the equipment, and suitable for the installation of anchors to attach the THV guide rails.

- The area around the shaker will need to be free of any ferromagnetic particles.

- Adequate and compliant incoming electrical power and appropriate disconnects for each piece of equipment will be needed. Each THV system is unique and these requirements will be provided to you by our Sentek Engineering Team.

- Adequate and compliant cooling water supply for the THV chamber and shaker cooling unit if equipped will be required. Each THV system is unique and these requirements will be provided to you by our Sentek engineering team.

- Compressed air supply for shaker payload support, trunnion isolation, isolation feet, and if equipped, the THV purge system.

- LN2 or CO2 compressed gas supply and method of exhaust if required for your system’s configuration. Each THV system is unique and these requirements, if needed, will be provided to you by our Sentek engineering team.

- Floor drain or drain pan system to capture any chamber condensate.

- Sufficient air conditioning capacity for maintaining the laboratory working environment while equipment is in use.

- Sufficient laboratory make-up air flow for air-cooled systems when blower unit is located outside of the testing area.